With the current trend of automating machinery and technological lines, the system SCADA control cabinet commonly used in production lines, workshops, and factories. The SCADA control cabinet system not only contributes to improving production quality, reducing operating time, ensuring safety, but also quickly integrating an intelligent management system for the factory. Join Tan Long to learn more about the SCADA control cabinet system in the article below!

What is SCADA control cabinet?

SCADA control panel is an industrial automation system, commonly used to monitor and control electrical equipment in a power distribution system or a manufacturing facility. SCADA stands for “Supervisory Control and Data Acquisition”.

SCADA control cabinets are used in many areas, from industrial power distribution systems to manufacturing plants and basic infrastructures such as water supply and waste treatment, helping to increase efficiency, reduce failures and improve power system management.

Structure of SCADA control cabinet

The SCADA control cabinet system is composed of the following basic components:

- Intermediate data collection station: This is a remote input/output device such as an RTU (Remote Terminal Units) or a PLC (Programmable Logic Controller) block, capable of controlling actuators such as sensors and signal converters to switching relays.

- Central monitoring station: Is one or more central servers where data is collected and processed.

- Communication system: Includes communication and telecommunications equipment, which has the function of transmitting data from an intermediate station to a server.

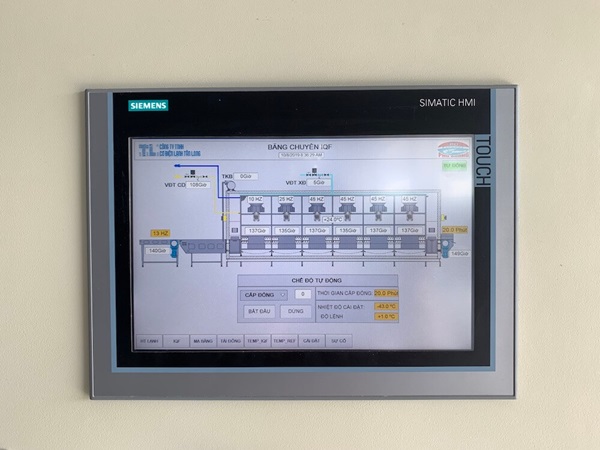

- HMI (Human Machine Interface) interface: A device that displays data processing for operators to monitor and interact with the system.

Operating principle of SCADA control cabinet

The operating principle of SCADA control cabinets is the integration of sensor components, control devices, communication networks and data management software to monitor and control industrial processes and infrastructure.

First, the sensors in the se4 system send data on parameters of the production process or infrastructure operation such as temperature, pressure, current or other parameters. Then, the data from the sensors is transmitted over the communication network to the central monitoring station, through communication devices such as RTUs or PLCs.

At the central monitoring station, SCADA software processes the received data, displays the information, and performs analysis algorithms to monitor and evaluate the system status. Based on the processed information, SCADA software can generate control signals to adjust or control the devices in the system, such as opening/closing valves, turning on/off machines, or changing settings.

Finally, the SCADA control panel system records historical data and generates reports on performance, failures, and critical events to support management and decision making.

Function of SCADA control cabinet

The main function of SCADA control cabinets is to help operators monitor, control and manage industrial processes or infrastructure efficiently and automatically.

- Data collection: SCADA control cabinets collect data from devices and sensors throughout the system, including information about temperature, pressure, flow, water level, voltage, current and other parameters related to the operating process.

- System status monitoring: SCADA displays information about the operating status of devices and processes in the system on a user interface. This allows operators to monitor and evaluate the performance and efficiency of the system.

- Remote control: Depending on the system configuration and features, SCADA control cabinets can allow operators to control devices and processes remotely through a user interface on the SCADA station.

- Alarms and warnings: SCADA control panels are capable of detecting faults or abnormal conditions and generating alarms or warnings to notify operators. This helps to minimize downtime and the risk of failure.

- Data storage and processing: SCADA control cabinets also have the ability to store data from devices and sensors in real time or historically. This data can then be used to analyze system performance, plan maintenance, and optimize production processes.

- Integration with management information systems: Depending on the specific requirements of the application, SCADA control cabinets can integrate with management information systems (MIS) to share data and information with other systems within the organization.

SCADA control cabinet specifications

| Rated voltage | 220~230VAC / 24VDC |

| Monitor screen | Have |

| Number of I/Os | 25-1000 |

| Analog Input/Output | 4-20mA ; 0-10VDC; -5 – 5VDC |

| Digital Input/Output | Dry/Wet 0-24VDC; Pulse |

| Connect | Ethernet IP, Profibus, CAN |

| Remote monitoring | Have |

Advantages of SCADA control cabinets

- Improve productivity: Data collected and analyzed through the SCADA system helps managers optimize production processes, thereby increasing efficiency and improving technology.

- Improve product quality: Analyze and process data instantly, thereby allowing managers to minimize errors and limit defective products during the production process.

- Reduce time and save costs on operation, maintenance and servicing: SCADA control cabinet systems help businesses reduce personnel in remote monitoring positions, while reducing costs for inspection, maintenance and repair trips.

- Safety features: SCADA replaces human monitoring and control in hazardous and toxic areas, while reducing the risk of operational failures.

- Investment preservation: The SCADA electrical cabinet system is “open-design”, allowing for adjustment and change according to scale, thereby continuing to invest in upgrading at low cost.

Applications of SCADA control cabinets

SCADA systems are widely used in many different fields and scales, from small businesses to corporations with many factories. Data collected from SCADA provides useful information on operating performance, equipment status, output and arising problems, helping to improve production processes and reduce maintenance costs. The system also provides important data reports so that administrators can evaluate existing resources and plan business strategies to achieve the highest production efficiency.

The fields and industries that use SCADA systems today include:

- Food and beverage production.

- Power plants, solar power and power stations.

- Pumping station and wastewater treatment plant.

- Steel, textile, pharmaceutical and chemical industries.

- Oil and gas industry.

- Recycling plant.

- Monitor building amenities such as temperature, humidity, lighting and other parameters.

Standard SCADA control cabinet design and installation process

- Customer requirements analysis: Tan Long will listen to customers' specific requirements to provide the most optimal solutions.

- System design and programming: Based on the requirements analysis, Tan Long engineering team will design the SCADA control cabinet system.

- Testing and inspection: Before deployment, the system will be inspected and tested to ensure proper and stable operation.

- Deployment and installation: After completing the inspection and testing, the system will be deployed and installed at the customer's location. Tan Long's technical team will perform the installation and connection of the equipment according to the previously determined design.

- User manual and support: Tan Long will guide customers on how to use the system, and provide technical support to resolve any problems that may arise and help the system maintain stable operation.

Consulting, installing and designing SCADA control cabinets

Tan Long's SCADA control system is built according to optimal value and investment standards with the most flexible and competitive solutions in the market combined with Industry 4.0 trends. Tan Long is always ready to consult, install, design stable, intelligent systems and combine with long-term system lifecycle management programs.

Tan Long will cooperate with customers from the beginning, providing solutions until making the final decision and signing the contract. The software is programmed by our own team of engineers, continuously updated to optimize the operation and control process for customers.

SCADA control cabinets manufactured by Tan Long at the factory are monitored and tested throughout the production process and are designed and manufactured to optimize the refrigeration system, ensuring reliability and saving operating costs for customers.

Tan Long - A reputable unit providing quality electrical cabinets

Tan Long is a unit specializing in providing technical solutions, designing and installing complete industrial refrigeration systems, cold storage, cold storage for businesses and related equipment. Come to Tan Long, you will get:

- Our team of technicians consults, designs, and installs contact freezers according to the scale and purpose of the business.

- Support full installation, on schedule.

- Full service, one-time quote.

- Transparent and clear contract

Tan Long Proud to be one of the leading units providing technical solutions, design, construction and installation of freezing equipment systems in Ho Chi Minh City. If you need to design and install a refreezing conveyor, please contact us immediately. Tan Long via hotline (+84) 933357058 for specific advice and support.